More than meets the eye: Storing materials safely

Date Posted: 04/02/2019

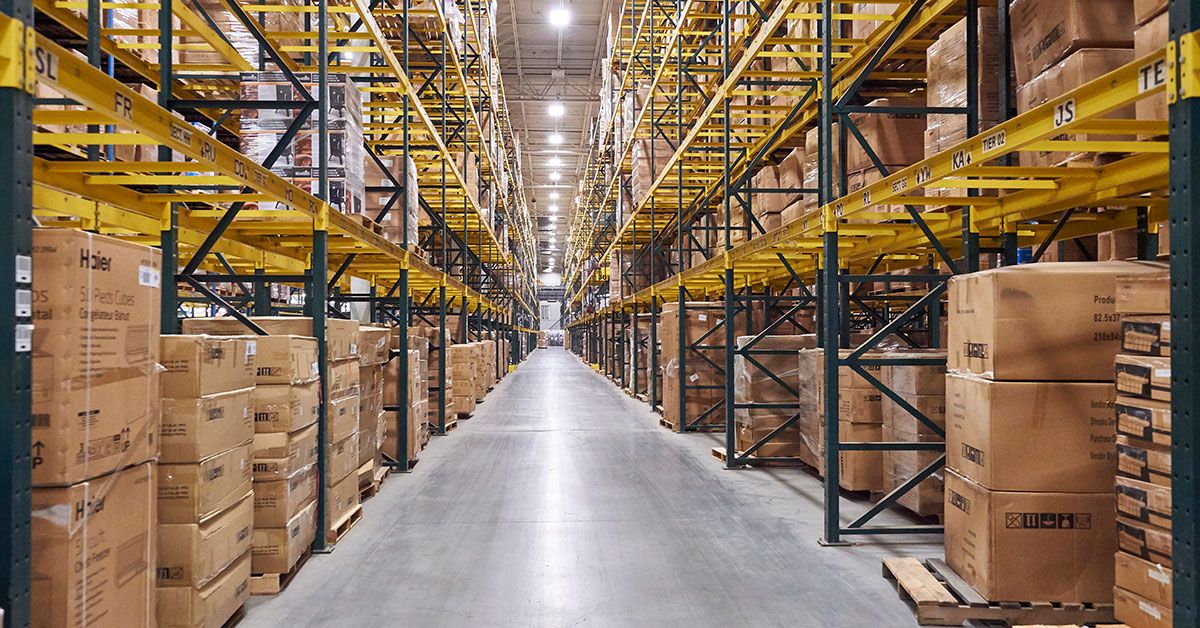

If a stack of materials looks off-balance (and you've most likely seen a wonky pile of pallets or boxes), the material needs to be restacked correctly. Remind employees to take the time to do it right the first time, so they don't have to waste time doing it over.

Storing materials may seem like a straightforward issue, but there are many hazards that can arise, and the regulations provide few answers. Paragraph (b) of 1910.176 says only "Storage of material shall not create a hazard" and provides general storage information, while paragraph (c)(10) of 1910.159 says there must be 18" of vertical clearance between sprinklers and stored materials.

Tips for storing materials

When training employees on proper stacking and storage, walk through the workplace and take photos of what things should look like, and what they should NOT look like (hopefully, you won't find any problems). You might also find images of improperly stacked material online. Then, share these tips with employees:

- Ensure stacked materials are stable and secure:

- Stack bags and bundles in interlocking rows to remain secure.

- Stack bagged material by stepping back the layers and cross-keying the bags at appropriate layers.

- Stack drums, barrels, and kegs symmetrically. If stored on their sides, block the bottom tiers to keep them from rolling.

- Train workers to be aware of factors such as the materials’ height and weight, its accessibility, and the condition of the containers where the materials are being stored when stacking and piling materials;

- Keep storage areas free from accumulated materials that cause tripping, fires, or explosions, or that may provide nesting areas for rats and other pests;

- Place stored materials inside buildings that are under construction and at least 6 feet from hoist ways, or inside floor openings and at least 10 feet away from exterior walls;

- Store flammable/combustible materials only in proper containers, cabinets, and locations. Separate noncompatible chemicals;

- Equip employees who work on stored grain in silos, hoppers, or tanks, with lifelines and safety belts;

- Ensure stored material does not block safety equipment, such as fire extinguishers, sprinklers, and eyewashes; and

- Ensure storage racking is anchored to the floor, in good shape, and contains load capacity rating. For guidance, review the manufacturer’s instructions and applicable ANSI standards.

How Safety Management Suite Can Help

E-mail Newsletter

Sign up to receive the weekly EHS Insider email newsletter for safety articles, news headlines, regulatory alerts, industry events, webcasts, and more.